Water Based Printing Vs. Plastisol Ink Printing

Water-Based Printing vs Plastisol Ink Printing: Which One is Right for You?

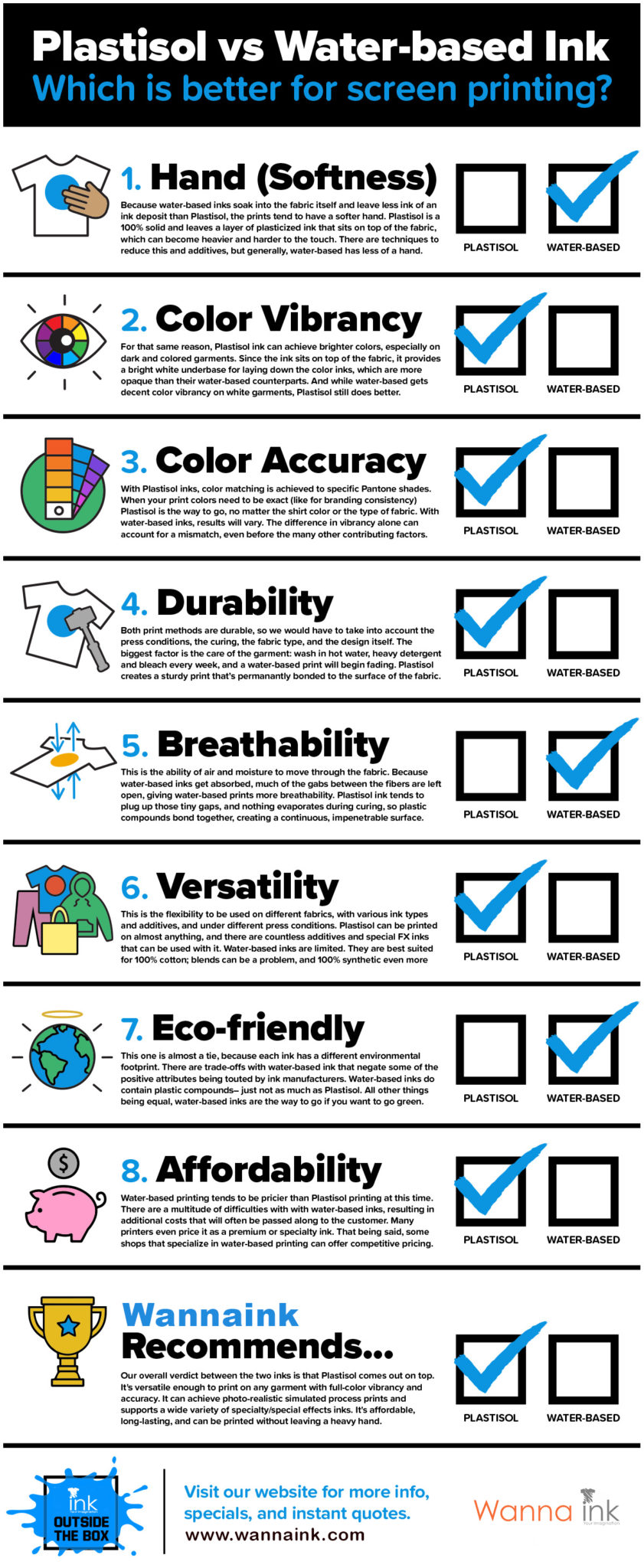

In custom apparel, screen printing remains the top choice for bringing your designs to life. The two main ink types that dominate are—water-based and plastisol ink. The battle between Water-Based Printing vs Plastisol Ink Printing has been ongoing for years. Each ink type has its unique benefits and challenges, impacting everything from color vibrancy to durability and environmental impact.

Which ink wins for your custom apparel? In this eye-opening guide, we'll compare Water-Based Printing vs Plastisol Ink Printing across 7 crucial factors—so you can make the best decision for your brand, business, or event.

Let’s Compare Water-Based Printing vs Plastisol Ink Printing

In the screen printing industry, the answer really depends on your needs. For light-colored cotton t-shirts with detailed, muted designs, water-based ink typically delivers the best results. On dark-colored tees with simpler graphics, plastisol ink usually performs better. Yet, even these guidelines vary based on your unique requirements.

Ultimately, you want an ink that produces a soft, lightweight print with precise color matching and vibrant output. You need prints that are breathable, capture intricate details, work well on various fabrics, and hold up through years of wear and washing—all while being cost-effective, easy to use, and eco-friendly.

No single ink type meets all these criteria perfectly. Therefore, the key is to determine which ink best suits the specific circumstances of your project. In this article, we will explore the top factors to consider when choosing between water-based and plastisol inks, providing insights for both customers and printers to make informed decisions.

1. Water based Ink Has a Softer Hand (Usually)

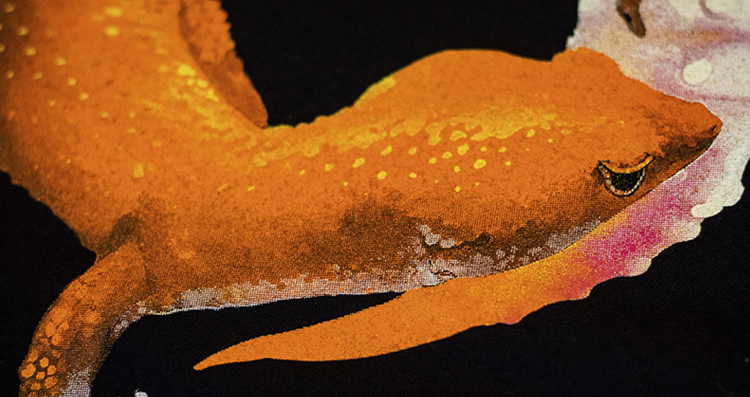

In screen printing, "hand" describes how a print feels on the fabric—its weight, texture, and overall softness. You can have prints that feel super soft and light (a definite yes) or rough and heavy (a no-go). Water-based inks typically produce prints with an exceptionally soft hand. In many cases, the print feels almost like the fabric itself.

Why Does Water-Based Ink Have a Softer Hand?

The key lies in the fundamental differences between water-based and plastisol inks. Plastisol is a plastic-based ink made from PVC particles or other polymers suspended in a plasticizer. When heated during curing, it solidifies into a thick layer that sits on top of the fabric, creating a heavier, more noticeable print.

Water-based ink, on the other hand, works differently. Although it isn't completely free of plastic, it is primarily water-soluble. The ink absorbs into the fabric, and when cured, the water evaporates. Pigmented binder compounds remain—resulting in a much thinner ink deposit. Sometimes, the print feels so soft that it appears as if the fabric is simply dyed.

The softer hand of water-based ink on darker garments is accomplished with the help of another type of ink.

Enhancing Softness on Dark Garments: The Role of Discharge Ink

For dark or colored garments, achieving a soft hand can be challenging. This is where discharge ink printing comes in. Used alongside water-based inks, discharge ink contains chemicals like formaldehyde that bleach out the dye from the garment. This process creates an almost white base, allowing the water-based ink to sit lightly on top. Discharge ink works best on 100% cotton, providing a soft finish that doesn't weigh down the fabric.

In contrast, printing dark garments with plastisol ink often requires applying a white under base to create opacity. This extra layer adds weight, resulting in a heavier hand—even before vibrant colors are added.

Bottom line: Water-based inks generally achieve a softer, lighter hand than plastisol inks. They offer a more natural feel and a lightweight finish, though they may not consistently deliver the same color intensity. When choosing your screen printing ink, consider whether the ultimate goal is a soft, comfortable print or a bold, vibrant finish.

2. Plastisol Ink Delivers Superior Color Vibrancy

When it comes to making colors pop, plastisol ink is in a league of its own—especially on dark garments. While water-based inks perform well on lighter fabrics, they simply can't match the saturation and brightness that plastisol brings to the table. If your goal is to create bold, dynamic designs that truly stand out, plastisol screen printing is your best bet.

Why Does Plastisol Ink Stand Out?

The secret lies in its thicker, heavier deposit. Plastisol ink forms a solid, plasticized layer on the fabric when cured, effectively blocking out the garment's color. This opaque base allows vibrant, eye-catching colors to shine through, whether you're using standard hues or speciality options like fluorescent, glow-in-the-dark, or puff inks.

The Difference in Practice

Water-based inks often produce muted colors on dark t-shirts. They're more transparent and struggle to achieve a bright white underbase—discharge printing can help, but it usually only results in an off-white finish. In contrast, plastisol ink's full opacity ensures that every detail is bold, bright, and brilliant.

Bottom Line: Plastisol ink remains the industry standard for designs that demand dynamic, vivid colors. Its ability to create a striking visual impact makes it ideal for projects where color vibrancy is paramount.

3. Plastisol Ink Offers Superior Color Accuracy

Plastisol ink isn't just about vibrant hues—it also delivers unmatched color accuracy. Thanks to its dense, opaque layer, Plastisol consistently achieves precise Pantone matches. Need your branding to be spot-on, like a specific bright red 185 C? With Plastisol, you get exactly that, regardless of the t-shirt color or fabric type.

Water-based inks have come a long way, but they still tend to miss the mark by a few shades. Their softer, more transparent finish can lead to slight color shifts from factors like dye migration or variations during curing.

In short, if you need precise, consistent colors for your custom apparel, plastisol ink is your best bet.

4. Both Inks Offer Exceptional Durability

When it comes to keeping your designs looking fresh, both water-based and plastisol inks are built to last. Water-based ink soaks into the fabric, becoming almost one with your t-shirt. Plastisol ink, in contrast, sits on the surface and forms a strong bond once cured.

Remember, proper curing is essential for any ink to perform well. The quality of the ink, the fabric type, and—most importantly—how you care for your garment all play a role in print longevity. Washing in hot water, using harsh detergents, or frequent exposure to bleach can wear out any print, no matter which ink you choose.

In short, whether you opt for water-based or plastisol, careful curing and proper care ensure your custom apparel will maintain its look for years to come.

5. Water-based Ink Has Better Breathability

Water-based inks offer excellent breathability for your custom apparel. They soak deep into the fabric, leaving many of the natural gaps between fibres open. This allows moisture to move freely through the garment, keeping it cool and comfortable.

In contrast, plastisol ink forms a thick, impermeable layer on the fabric's surface. Because it doesn't absorb into the fibres and cures into a solid film, it can block air and moisture. This often results in that notorious "sweat patch" on your t-shirt.

For designs where comfort and moisture control matter, water-based ink is the clear choice.

6. Plastisol Ink Offers Exceptional Versatility

Plastisol ink is incredibly flexible—it works on a wide range of fabrics, with different additives, and under various press conditions. This is one of the main reasons it’s been the go-to choice for screen printers for decades, even as DTG printing makes its way into the industry.

Plastisol print can be done on just about anything else. (That doesn’t mean you should, but you can)

Water-based inks, by comparison, are best suited for 100% cotton. Once you start mixing in synthetic fibers, like polyester, the performance drops off because these inks simply don’t absorb as well. Print on polyester with water-based ink, and you’re likely to face problems.

Bottom line: If you need high-quality prints on different types of garments, plastisol ink gives you the freedom to work with a variety of fabrics without compromise.

7. Water-Based Ink: A Greener Choice (Slightly)

Today’s market is more eco-conscious than ever, and many brands are embracing greener production methods. Water-based inks are becoming popular because they avoid the harmful PVC and phthalates common in other inks. Although they’re not perfect, water-based options reduce toxic chemicals, making them a more sustainable choice for screen printing. This shift helps brands meet environmental goals while still delivering quality prints.

How Much Better Are Water-Based Inks for the Environment?

Many claim that water-based inks are a greener option—but the truth is more nuanced. While these inks do eliminate PVC, they still include some plastic components, like acrylic binders. They also rely on solvents that evaporate during curing. Although water is the main ingredient, manufacturers often add co-solvents such as formaldehyde and alcohol, which require proper ventilation and safety measures.

Another point to consider is the curing process. Water-based inks need more time and energy to dry than plastisol inks. This extra energy use can lead to higher overall environmental impacts. In many cases, the waste generated—similar to other plastic residues—ends up in landfills.

In short, water-based inks do offer certain environmental advantages, but they aren’t a completely green solution. Their true eco-friendliness depends on how they’re handled, cured, and disposed of.

What’s bad about PVC?

Polyvinyl chloride, or PVC—often called vinyl—has earned a reputation for being problematic. Sure, like any mass-produced chemical, it has its issues, but many of the criticisms are exaggerated or even debunked.

PVC is one of the most common plastics used worldwide due to its versatility and reliability. It’s exceptionally recyclable, requires minimal upkeep, and won’t off-gas or leach harmful chemicals when it comes into contact with water. Its manufacturing process is energy-efficient, and its lightweight nature significantly reduces the carbon footprint during production and shipping.

Despite a growing push to find alternatives, no substitute has yet matched the versatility, consistency, and dependability of plastisol ink. Ultimately, how “green” a print shop is depends more on its management practices than on the specific ink or material used.

Bottom line: While PVC isn’t perfect, many negative claims are overblown. It remains a practical choice for many industries, offering environmental benefits that often go overlooked.

Plastisol Ink Offers Lower Costs (Usually)

While water-based inks are popular for their soft-hand prints, they often come with a premium price tag. Many printers treat water-based ink as a speciality product, and the extra challenges in using it mean those added costs usually get passed on to you.

On the other hand, plastisol ink is a more affordable option. Its straightforward application and quicker curing process allow print shops to keep expenses in check—and those savings go directly to you. At Wannaink, we work hard to offer competitive prices without compromising quality.

In a nutshell, if you're looking at your budget, plastisol ink is the smart choice, delivering excellent results without extra costs.

Pro Tip: Plastisol Ink is Easy to Use and Yields More

For printers, every step counts. Plastisol ink stays stable, so you can use it straight from the bucket to the screen, then print, dry, and pack—all without fuss. If you're a printer, this ease of use and higher yield really makes a difference. (If you're just ordering T-shirts for your team, you probably won't notice this.)

Water-based inks, in contrast, are trickier. They’re thicker and prone to issues, so print shops often avoid them. They require special additives—like low-cure agents, dye blockers, and high-solid acrylics—to work properly, and they tend to dry out fast.

Wannaink Recommends: Plastisol

Our experience shows that it delivers full-color vibrancy and precise prints on any garment. It even handles photo-realistic images and a variety of special-effect inks. Plus, it’s affordable, durable, and doesn’t leave a heavy feel on the fabric.

When it comes to quality, ease of use, and reliability, plastisol ink comes out on top.

For a review of this article, see the infographic below. When you’re ready to create your design and order custom printing, get in touch with an apparel consultant at +91 965-454-6400.