Offer more to your customer base allowing vibrant, full-color, all-over prints

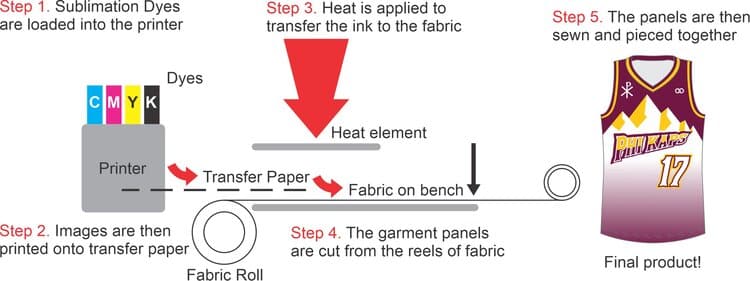

Sublimation printing is the method by which color is transmitted to fabric through heat. The artwork is printed on special transfer paper placed on the garment, and heat is applied so that the ink gets absorbed by the fabric. This process makes a more soft hand feel and breathable to the garment fabrics. The significant aspect is that the letters, numbers, and logos don’t fade, wear off in the wash!

Dye-sublimation printing is a good printing method that allows you a full color, vibrant and all-over print.

How it Works

Benefits of Sublimation Printing on t-shirts

- There’s no limitation on colors and any additional costs.

- It provides vibrant colors and is suitable for photographic images.

- It can create complicated printing patterns on the front and rear of your sublimated uniforms.

- The soft hand feel of the print.

- Sublimation print won’t fade, crack or peel.

- Transform your robe by adding a heat transfer such as hotfix glitter, rhinestones, or foil. It never goes out of style.

White or light-colored fabrics, usually polyester or polycotton, are best for sublimation. You can’t do sublimation printing on t-shirts with 100% cotton fabrics.

For best results, 100% polyester is a must. It can also work with polymer-coated items like mugs, coasters, telephone boxes, mouse pads, towels, bottles, etc.

Dye-sublimation printing is the most eco-friendly and sustainable process in sportswear, textile printing, and production. It has zero wastage and water is not necessary for the sublimation process. It is the most effective and cheapest way to produce a full-color print on polyester fabrics.